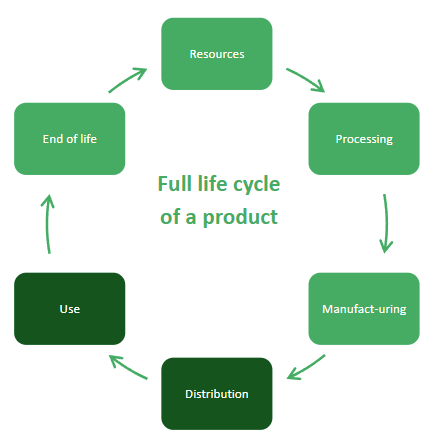

A comprehensive approach to the life cycle of a product is essential for effective sustainable waste management. The key challenge lies in reducing the environmental impact of products from the initial extraction of resources to the final stages of disposal and end-of-life management.

In this context, Life Cycle Assessment is emerging as a key tool to help identify environmental “hotspots” to take appropriate actions and optimise environmental performance of a product without compromising its functionality. From this perspective, the WORM project, through deliverables D1.2 and D1.3, has focused on comparing the environmental performance of bio-based materials (starch-based bioplastics) with conventional materials (fossil-based plastics) throughout their life cycle.

Figure 1: Full life cycle of a product

Although the latter are still the most widely used today due to their durability and cost effectiveness, their environmental impact is devastating. Their production, which relies on fossil resources, generates high levels of greenhouse gas emissions, contributing significantly to climate change. In addition, their persistence in the environment is a major problem in waste management, especially when incinerated, the most widespread and polluting method. It is therefore essential to explore more sustainable alternatives to reduce their environmental footprint.

Addressing these challenges, the LCA was further refined to identify critical stages where the environmental impact of materials is most significant. To achieve this, the assessment was divided into two main phases:

- Production, which was identified as the primary source of pollution and plays a key role in the initial environmental footprint of materials.

- Waste management, comparing different disposal methods with a particular focus on incineration, which remains the most widely used technique for treating hazardous waste

The analysis highlights one clear conclusion: bio-based materials consistently outperform conventional products from the production phase through the end-of-life management. Unlike fossil-based plastics, which persist in the environment and cause long-term pollution, bio-based plastics can be a more sustainable alternative, especially when designed to be biodegradable.

Biobased materials, a promising but imperfect alternative

The study shows that bio-based materials have the potential to be more environmentally sustainable in the long term, but achieving true environmental benefits requires careful consideration of their full life cycle. Their production generates fewer greenhouse gas emissions, reduces the use of fossil resources and thus contributes to a smaller ecological footprint. However, their production relies on agricultural practices that can have significant environmental impacts. The production of bioplastics requires the use of synthetic fertilisers and pesticides, which leads to eutrophication and freshwater ecotoxicity. To address this challenge in the long term, one alternative would be to switch to more environmentally friendly agricultural production methods, such as organic agriculture.

End-of-life management

If bio-based alternatives have the potential to be more environmentally friendly during production, this advantage also extends to their end-of-life phase. Indeed, bio-based materials – especially if they are biodegradable – almost always outperform conventional materials at this stage of the life cycle.

However, waste management still relies on highly imperfect practices such as landfilling, open burning, open dumping, and incineration which pose serious risks to human health and the environment. Whether dealing with bio-based or conventional materials, open burning and incineration remain among the most polluting methods and should be avoided at all costs.

Given the limitations of traditional techniques, the WORM project aimed to assess the potential for non/less-destructive alternatives for sterilizing waste before sending it to a sanitary landfill. One of the most promising solutions is autoclaving, a steam sterilisation process that significantly reduces toxic emissions and therefore the environmental impact of waste. Even with a low operating cost, it remains costly to implement and requires significant amounts of water and electricity to operate. Other alternatives, such as microwave treatment, have shown promising results by disinfecting waste without combustion or fine particle emissions. While it is considered one of the most effective and environmentally friendly methods, it relies heavily on electricity, which may limit its environmental benefits. Finally, chemical disinfection is another viable but more controversial option while the use of chemical products can be harmful to human health and the environment.